News + Insights

News + Insights

Sunnen Products Company Announces Launch of PGA-1000 Air Gage: Developed to Deliver New Precision and Confidence in Benchtop Dimensional Measurement

Introducing Sunnen's PGA-1000 Air Gage, the latest expansion of its longstanding expertise in bore gaging. Sunnen’s benchtop system delivers a new level of performance, reliability, and confidence in dimensional measurement, making it an ideal solution for customers seeking precision and trust in their results.

Read moreLet's Congratulate Josh Allen on being a 2025 ORBIE Award Finalist!

We’re proud to share that Josh Allen, Director, Global IT has been named a Finalist for the 2025 ORBIE CIO of the Year Award!Since 1998, the St. Louis ORBIE Awards have recognized CIO leadership, and the organization is considered the premier technology executive recognition program in St. Louis. The CIO Orbie Awards recognize technology leaders who drive innovation, enable growth, and inspire their teams to achieve excellence. The 2025 St. Louis CIO ORBIE Awards are on December 11 at The Chase Park Plaza Royal Sonesta Hotel. Finalists and winners are selected by an independent peer review process, including former ORBIE winners. Josh Allen’s ORBIE nomination comes as no surprise to his colleagues at Sunnen. Josh’s leadership and vision have been instrumental in strengthening Sunnen’s IT organization and building a solid foundation for the future. Under Josh’s direction, Sunnen’s digital transformation is taking shape. Projects like the following are already underway: Modernizing IT Infrastructure Creating Cost Efficiencies and simplified software solutions for a One Sunnen Global approach Upgrading the ERP system Obtaining Cybersecurity Maturity Model Certification Implementing AI with additional projects scheduled to launch soon. We’re excited for all of the exciting technological developments here at Sunnen, and we’re thrilled to have a talent like Josh Allen on our team. Good luck in December! To learn more about the ORBIE awards, click here: 2025 St. Louis ORBIE Awards | St.LouisCIO

Read moreBeyond the Grit: Understanding the Role of Abrasive Technology in Modern Manufacturing

In the world of precision manufacturing, precision bore honing abrasives do more than polish a surface, they shape the way components perform across their entire lifecycle. From ensuring the seal integrity of aerospace hydraulics to fine tuning combustion chambers in remanufactured automotive engines, abrasive technology quietly plays a critical role in producing parts that are safer, more efficient, and longer lasting. Despite their widespread use, engineered abrasives are frequently misunderstood as simple one-size-fits-all tools that are easily interchangeable. This oversimplification masks the true potential of abrasive technology. To understand the full impact of precision bore honing abrasives, it helps to think of them not as consumables, but as engineered cutting tools with performance characteristics that must match, and even anticipate, the demands of new materials and applications.

Read morePrecision Engineered: How Sunnen’s HES External Honing Machine Transforms Large-Scale Manufacturing

Sunnen’s HES External Honing Machine stands at the forefront of industrial innovation, offering manufacturers new possibilities for handling the most demanding applications and oversized components. This advanced honing solution merges precision engineering with user-friendly operation, delivering outstanding stock removal rates, perfect surface finishes, and reliable performance for an incredibly diverse range of large parts and materials.

Read moreSunnen's SV Systems: Revolutionizing High-Precision Honing

In the world of precision manufacturing, achieving flawless bore finishing is paramount. Sunnen Products Company, a global leader in the field for over a century, continues to push the boundaries of what's possible with its advanced SV Systems for high-production honing. These vertical honing systems are engineered to deliver unmatched precision, flexibility, and efficiency, making them an ideal solution for a wide range of industrial applications.

Read moreSunnen's All-Electric HTA Tube Hone is Setting New Standards in Bore Finishing for Hydraulic Cylinders

Sunnen Products Company has once again demonstrated its leadership in high-precision bore finishing with the entry level HTA Tube Hone, an all-electric machine designed to set a new benchmark in tube honing performance replacing manual honing for tube applications.

Read moreSunnen Launches MB-30LO Honing Oil: A New Era in Precision Metalworking

Sunnen Products Company sets a new benchmark for metalworking and aerospace-grade honing with the introduction of the MB-30LO Honing Oil. Engineered for both general machining and critical aerospace applications, MB-30LO brings together cutting-edge reformulation from the original MB-30 and comprehensive safety for demanding manufacturing environments. Its low-odor, ultra-low VOC profile ensures improved air quality and operator comfort, while meeting the strictest environmental standards with full ASTM1868-10 and SCAQMD compliance. The absence of hazardous classification under OSHA streamlines handling and lifts workplace safety standards even further. Beyond its impressive safety credentials, MB-30LO is a true workhorse for high-precision machining. The oil supports a wide array of processes, including drilling, tapping, reaming, screw machining, and honing, all with optimal lubrication due to its 26cSt viscosity at 40°C. Its distinctive dark brown-amber color allows easy identification, and a high flash point above 110°C reduces fire risk in demanding industrial settings. The specific gravity of 0.92 at 60°F ensures compatibility across systems, and a five-year shelf life guarantees long-term reliability for manufacturers. Transitioning to MB-30LO is effortless. It is designed for seamless drop-in compatibility with current Sunnen oils such as MB-30, LT9X, SHO965, and LP8X. Machine top-offs require no complete flush, making upgrades simple and cost-effective. Sunnen’s advanced formula also reduces the presence of odor-causing ingredients, supporting superior workplace environments that prioritize employee comfort and product safety. For those looking to achieve post-honing cleanliness, MB-30LO pairs perfectly with aqueous detergent washes, ensuring that every part meets the highest standards before leaving the facility. Proudly made in the USA, Sunnen’s MB-30LO Honing Oil stands as a testament to the company’s commitment to quality, innovation, and reliability. Manufacturers in aerospace, automotive, energy, hydraulics, medical, and beyond can depend on MB-30LO to deliver long-term performance and unmatched process versatility, continuing Sunnen’s legacy as a leader in precision metalworking solutions.

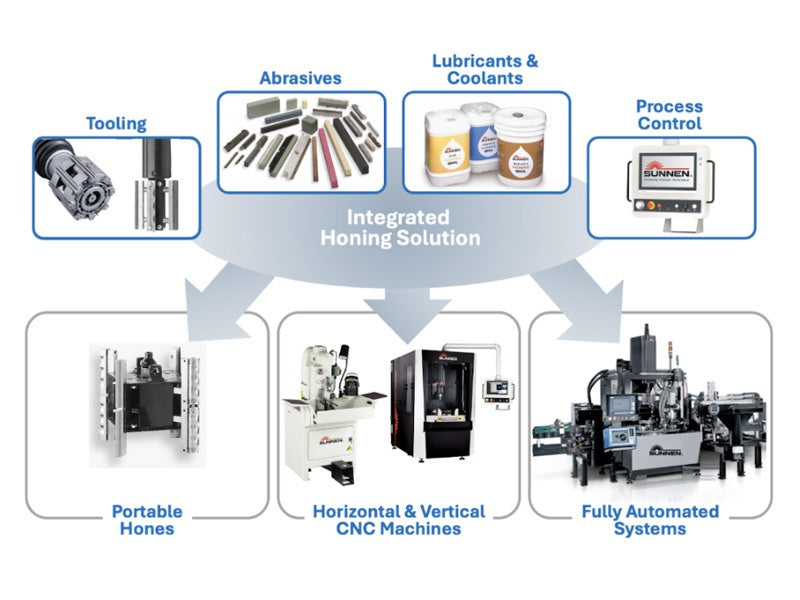

Read moreMastering Precision Machining: Perfecting Honing with an Integrated Approach

Honing is a precision manufacturing process that plays an increasingly vital role across industries, driven by the growing demand for cylindrical bores with ultra-tight tolerances and flawless surface finishes.

Read moreHydraulic Cylinders Reconditioned with Low-Cost Honing System

Hydraulic Cylinders Reconditioned with Low-Cost Honing System — Machine Pays for Itself in Less Than a Year

Read moreGun Barrel Honing System Hits Bullseye for Pac-Nor

Manufacturing precision rifle barrels has always been something of an art that involves hand lapping of the bore surface twice, before and after the rifling profile is cut or swaged in by a rifling button.

Read more

See What We're Working On

Visit us at one of our upcoming trade shows for an in-depth look at Sunnen’s complete line of machines, tooling and abrasives.