Custom Solutions

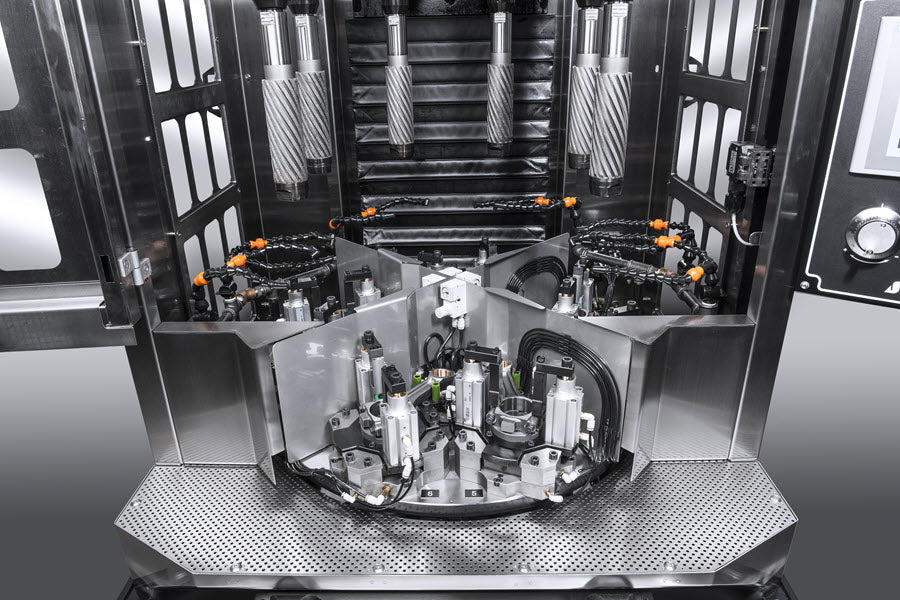

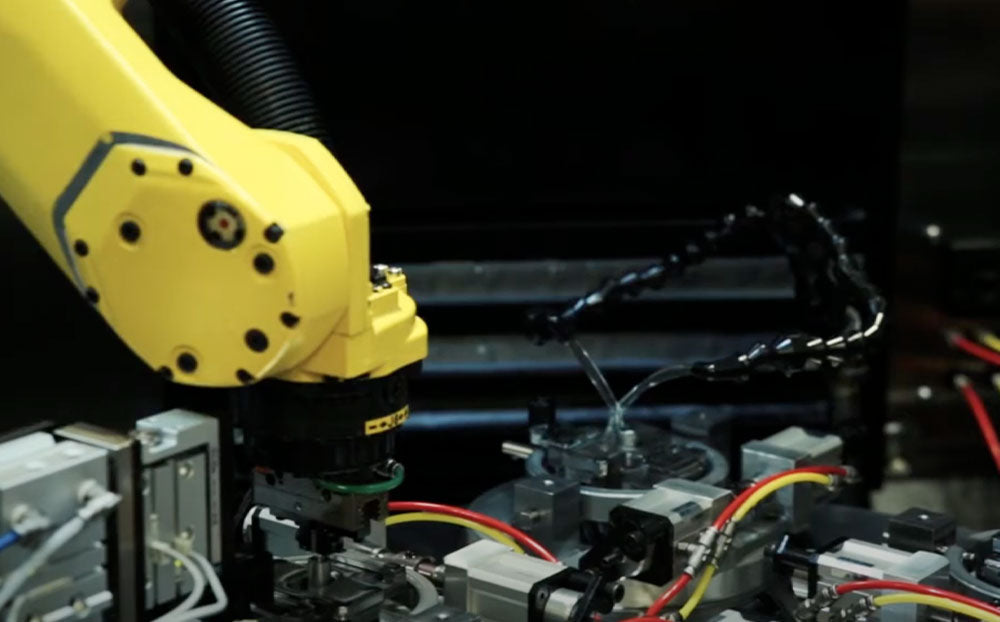

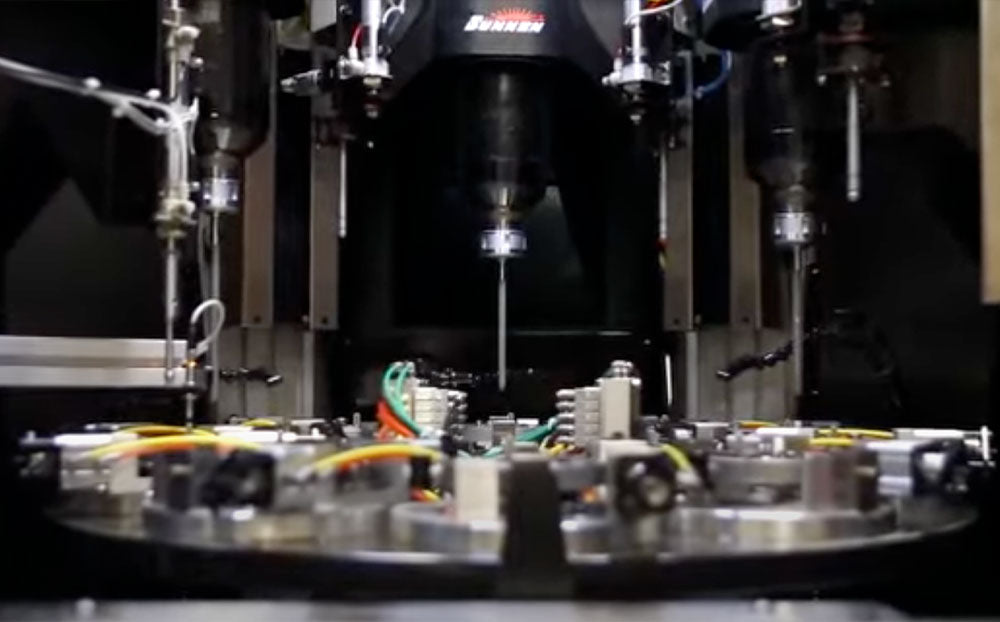

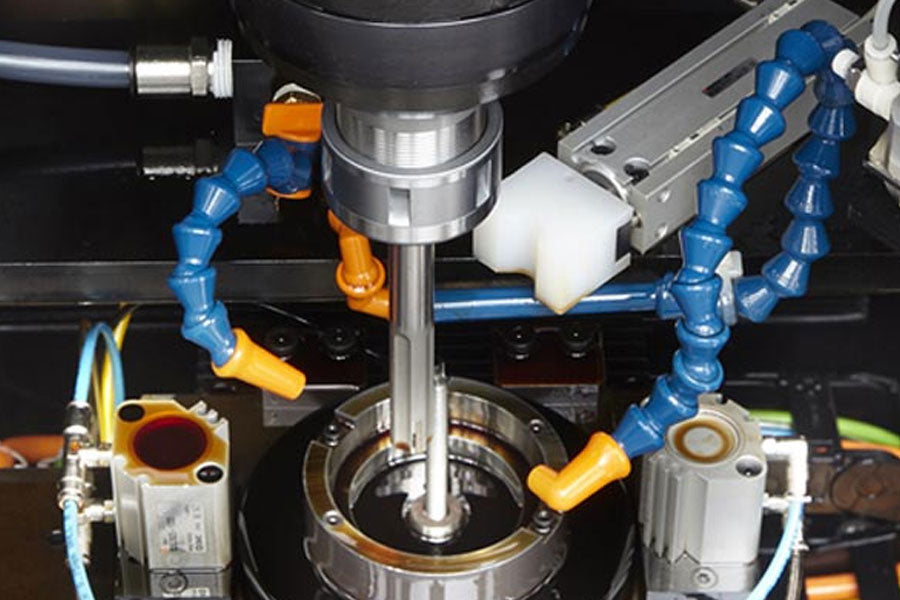

Custom Solutions for Complex Needs

True precision only comes from a machining process as unique as the operation. Sunnen creates one-of-a-kind solutions for bore creation, sizing and finishing. Across dozens of industries and countless applications, our custom systems deliver unmatched consistency.

Your Partner in Precision

Sunnen’s custom solutions are born from trusted partnerships with our customers. When we’re on your floor, we’re on your team. You’ll find us tweaking equipment, analyzing data and doing everything in our power to keep your facility running smoothly.

Innovation Meets Integration

We’ve seen it all—and we’ve made it work. View our case studies showing how Sunnen has created custom honing solutions for some of the most exacting applications and high-volume production lines.

Training

Hands-On Training & Support

A honing, lapping or deep hole drilling machine is only as good as the team behind it. That’s why Sunnen provides on-site training for every customer. These sessions are tremendous opportunities for us to calibrate machines, train operators and drive new efficiencies in the manufacturing process.

Learn From the Best

Sunnen takes a comprehensive approach to training. We’re not satisfied with teaching you how to use a machine. We’d rather show you how the machine fits into your whole operation, and how it works in harmony with the tooling and coolant to provide the perfect finish. With each training session, we bring a lifetime of honing experience, a wealth of technical expertise and a commitment to higher performance.

Here To Help—Whenever You Need It

Our commitment to training goes beyond installation. Whether you’ve just hired a new operator or are preparing for a new application, we’re always happy to come by and lend a hand. Our training programs are highly customized to your facility, your team and your needs. We have experts in installation, maintenance and application support ready to assist.

Process Development

Precision by Design: Process Development Services

Process development is how Sunnen puts our decades of honing and deep hole drilling experience to the test. When our customers embark on ambitious projects, like new applications or assemblies, they come to us first. We leverage every resource we have to create the right honing procedures and workflows for their demanding needs.

Led by Experience

We’re not just honing parts anymore—we’re honing processes. And we’re not afraid to get our hands dirty. Sunnen technicians lead the charge to design productive honing platforms for our customers ’operations. Whether they require a custom buildout or something off the shelf

Backed by Technology

Sunnen’s Advanced Technology Center is home to all the latest Sunnen machines, tools and abrasives, plus a full range of metrology instruments . They allow us to refine and test levels of performance our customers could never achieve on their own. The result is a honing system that’s been thoroughly vetted and validated—before it ever reaches our customers’ facilities.

Maintenance + Repairs

Maintenance & Repair On-Site Support

Sunnen’s global service team is at your disposal for all maintenance needs. Our field technicians provide on-site troubleshooting and repairs for all Sunnen products.

Sunnen's Service Agreement

We stand by our work. That’s why Sunnen provides support and replacement parts for every machine years after its model is discontinued. We make every effort to accommodate customer requests to keep their machines up and running. In addition, Sunnen also offers comprehensive preventative maintenance solutions. Contact your sales representative for more information.

Warranty

Unmatched Commitment

Every Sunnen machine is built to last. Our name is recognized around the globe for durability and reliability. Now, we’re cementing that reputation with a new warranty that surpasses anything else in the industry.

Best-in-Class Warranty

Sunnen’s standard warranty covers every machine for three years or 6,000 spindle hours, whichever comes first. It applies to all Sunnen base machines and factory-installed options. We also cover all custom fixtures, automations, tooling, gages and other accessories with a revised one-year warranty.