Honing

Honing Process: The Efficient Solution for Bore Sizing and Finishing

Honing is the ultra-precise bore machining process trusted by job shops and manufacturers to create parts that perform at the highest levels of speed, reliability and efficiency. No boring or grinding process is capable of delivering such precise levels of roundness, straightness and surface geometry at a lower cost per part.

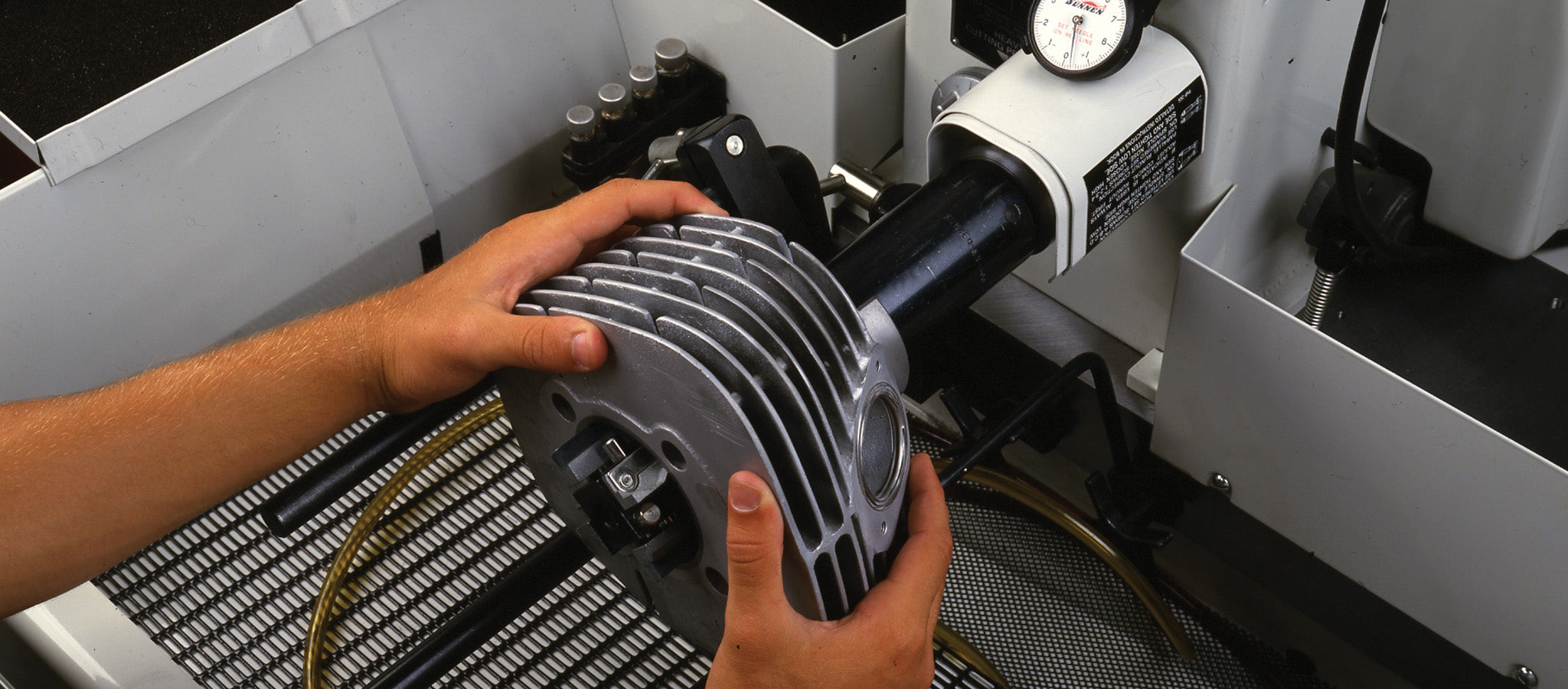

How Honing Works

The honing process uses a set of engineered abrasive stones arranged around a tool or mandrel. The tool spins as it is stroked in and out of the bore, while at the same time the abrasive stones are expanded against the wall of the bore. Together these rotational and reciprocal movements grind away at the interior surface of the bore to achieve precise bore geometry and surface finish.

Honing is commonly used for:

- Stock removal

- Tightening tolerances

- Polishing bores

- Finishing bores

Typical honing applications include:

- Hydraulic cylinders, valves and other hydraulic components

- Gun barrels

- Engine cylinders, cylinder sleeves, pistons and connecting rods

- Diesel fuel injector components

- Small Engines

Lapping

The Lapping Process: When Precision Is the Only Option

The lapping process is a specialized bore finishing procedure for those applications with extremely tight tolerances. It goes beyond the core capabilities of even the most advanced honing process to deliver cylindricity within 0.000060” (0.0015 mm); straightness within 0.000040” (0.0010 mm); and roundness within 0.000015” (0.0004 mm).

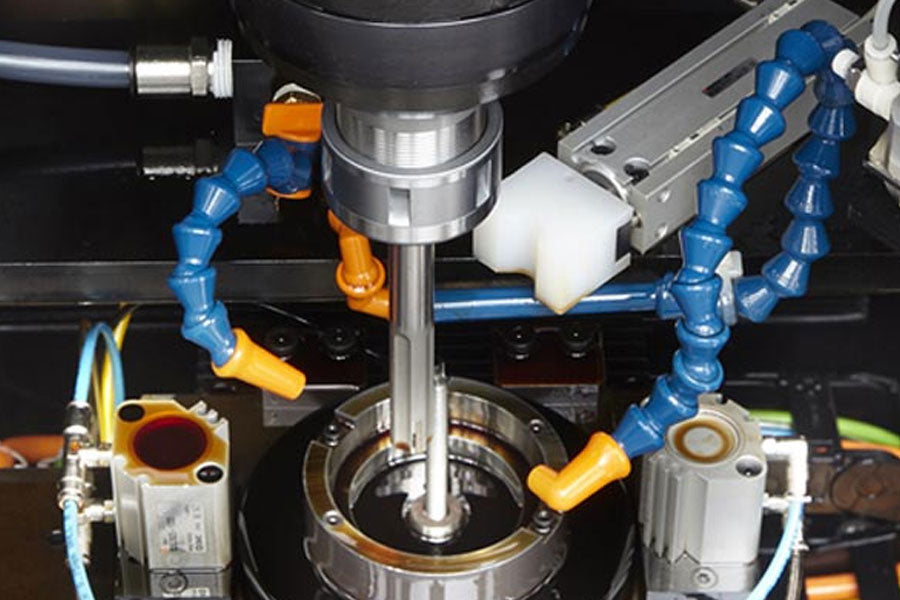

How Automated Lapping Works

At one time, the lapping process was a labor-intensive, manual procedure with a high margin for error. Today, Sunnen is the exclusive provider of automated bore lapping solutions. Sunnen’s patented machine uses a tool known as a lap, which resembles a honing mandrel but with grooves instead of abrasive stones. As the lap enters the bore it spreads a loose abrasive compound between the tool and the wall of the bore. As the tool rotates and reciprocates within the bore the abrasive compound removes excess material and creates a uniform surface finish. The machine periodically gauges the size of the bore and continues the lapping process until the bore is within specifications…all without operator intervention.

Automated Lapping Is Used To:

- Improve consistency of finished parts

- Reduce reliance on human operators

- Reduce potential for repetitive motion injuries associated with manual lapping

- Improve workplace safety by eliminating manual processing

- Tighten tolerances in bore diameter, roundness and straightness

Typical bore lapping applications include:

- Piston pumps and other aerospace parts

- Hydraulic valves and sleeves

- Thin-walled parts that are prone to distortion when honing

Lapping Products

Skiving + Roller Burnishing

Skiving and Roller Burnishing Process

Skiving and roller burnishing is a two-in-one bore sizing and finishing process that delivers high levels of precision at lightning-fast speeds. Skiving and roller burnishing process is up to 70% faster than traditional honing, making it an ideal solution for finishing hydraulic cylinder tubes in mass-production environments.

High-Speed Finishing for High-Production Manufacturing

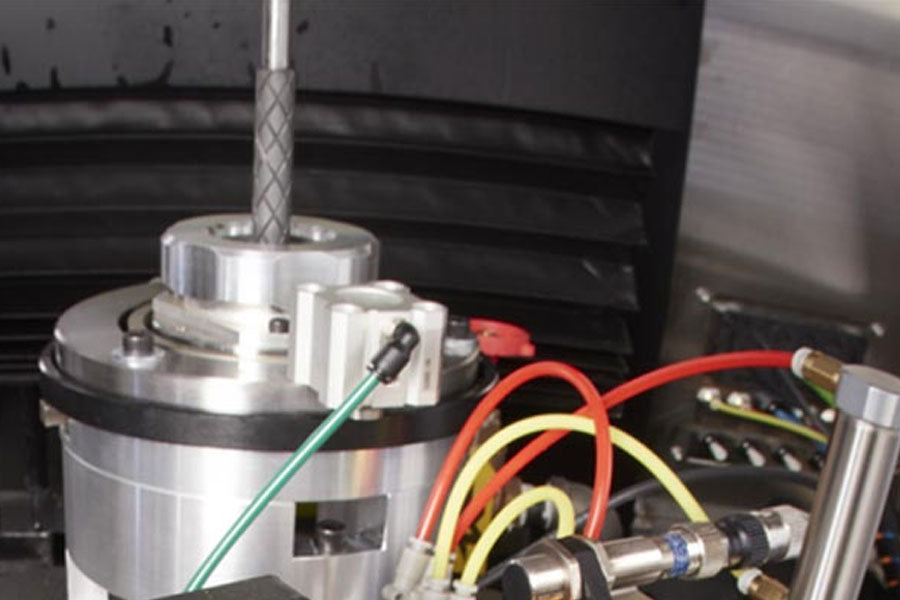

The skiving and roller burnishing process uses a unique combined skiving and roller burnishing tool that performs both skiving and roller burnishing in one pass through the bore.

The front section of the tool contains carbide cutters that remove material (skiving process). The second section of the tool contains hardened rollers that deform the peaks created by skiving and create an extremely smooth surface finish (roller burnishing process). The combination of these two processes creates a very fine surface finish with a typical RA of 0.05-0.20 µm.

Skiving + Roller Burnishing Is Typically Used To:

- Improve surface finish—as fine as .10 – .15 microns (4 to 6 micro-inches) RA on average

- Improve size control—tolerances within 0.0254 mm (.001 inch) on average

- Increase surface hardness

- Improve fatigue life

Typical Skiving + Roller Burnishing Applications Include:

Hydraulic cylinders/components for industries such as

- Agriculture

- Heavy-duty construction

- Mining

Deep Hole Drilling

Higher Precision From the Start - The Deep Hole Drilling Process

Deep hole drilling is the process frequently used for initial hole generation in large-scale industrial parts. When combined with Sunnen’s industry-leading bore finishing operations, deep hole drilling delivers exemplary levels of precision and efficiency to a wide variety of manufacturing applications.

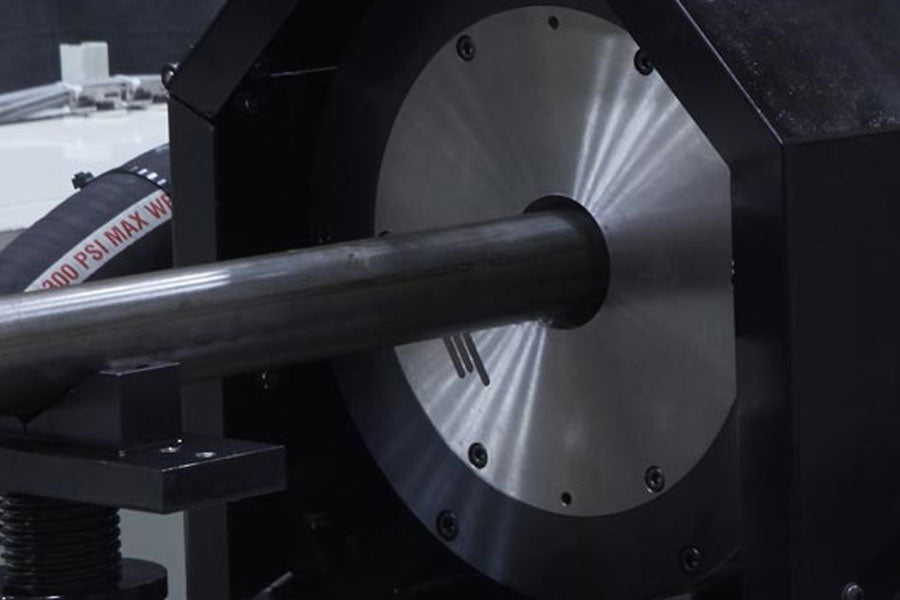

How Deep Hole Drilling Works

The deep hole drilling process was first developed in response to a growing demand for straight, accurate gun barrels. The process is now commonly used for machining any hole with a large diameter-to-depth ratio. Although many of the basic principles of drilling still apply, deep hole drilling employs various machine set-ups. The machines use ultra-high pressures to cut and remove chips evenly without damaging the workpiece.

The deep hole drilling processes are designed to:

- Achieve tight diameter control and bore straightness

- Allow easy setup and operation

- Accept a wide variety of workpieces

- Reduce changeover time and increase part production

Deep Hole Drilling Products

We know there’s more to machining than the machine. Sunnen is proud to be a total solution provider of machinery, tools, abrasives and accessories that seamlessly work together. Our complete line of honing oils/coolants and custom-designed abrasives can also improve the operation of non-Sunnen honing systems, with a standard of quality worthy of the Sunnen name.

Beyond machinery, Sunnen provides:

- Tooling

- Abrasives

- Oils & Coolants

- Bore Gaging

- Fixturing

- Automated parts handling

We’re On Your Team

We stand by our work and support our customers. Sunnen is the only company in our industry to offer a standard three-year warranty on every machine we make. We also offer machine installation, service and preventative maintenance to keep your operations running smoothly and address any emerging manufacturing challenges.